Global Plastic Recycling Machine Market: By Machine Type (Granulators, Shredders, Pelletizers, Mixer, Extrusion Machines, Crushing Machines, Agglomeration Machine, Plastic Waste Washing Machine, Drying Machines); Application (Post Industrial Recycling, PET Improvement, Post Consumer Recycling); Distribution Channel (OEMs, Aftermarket); Region—Market Size, Industry Dynamics, Opportunity Analysis And Forecast For 2024–2032

- Last Updated: Jul-2024 | Format:

![pdf]()

![powerpoint]()

![excel]() | Report ID: AA0523440 | Delivery: 2 to 4 Hours

| Report ID: AA0523440 | Delivery: 2 to 4 Hours

Market Scenario

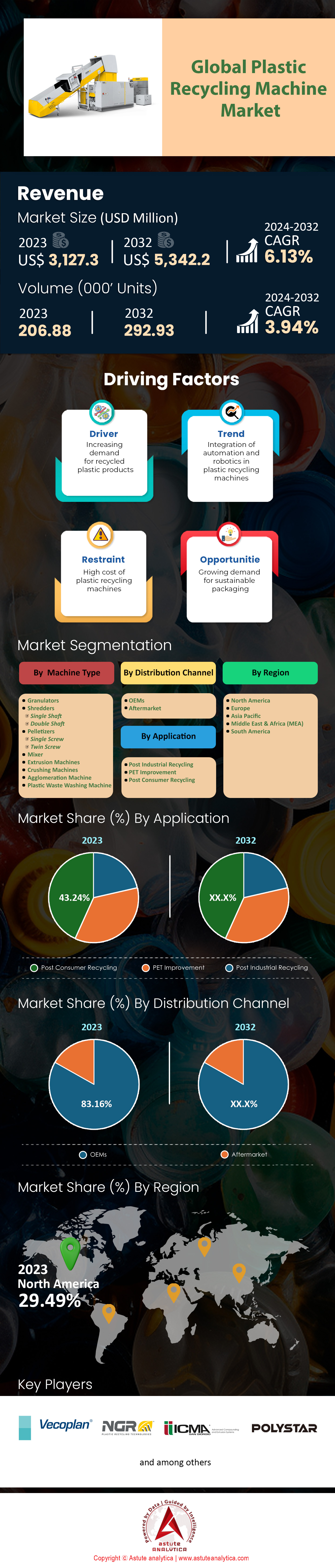

The global plastic recycling machine market exhibited robust growth in recent years, generating a revenue of US$ 3,127.3 million in 2023. This positive trend is expected to continue over the forecast period, 2024-2032, with a projected valuation of US$ 5,342.2 million by 2032. The market is anticipated to grow at a compound annual growth rate (CAGR) of 6.13% during this period.

Several factors are driving the growth of the plastic recycling machine market. There is an increasing global awareness about the environmental impact of plastic waste, leading to a rising demand for recycling solutions. Governments, organizations, and individuals are actively seeking ways to reduce plastic pollution and promote sustainable practices. Furthermore, stringent regulations and policies imposed by governments worldwide to curb plastic waste have stimulated the adoption of plastic recycling machines. These regulations incentivize businesses to invest in recycling infrastructure and ensure proper waste management practices. As a result, the demand for plastic recycling machines is expected to rise significantly.

Technological advancements play a vital role in propelling market growth. Ongoing research and development efforts focus on enhancing the efficiency and effectiveness of plastic recycling machines. Innovations in sorting, cleaning, and processing technologies enable the production of higher-quality recycled plastic, making it more attractive for manufacturers.

To Get more Insights, Request A Free Sample

Market Dynamics

Drivers

Increasing Demand for Recycled Plastic Products

The global plastic recycling machine market is experiencing a significant boost due to the increasing demand for products made from recycled plastic. These products are manufactured using plastic that has been collected, sorted, cleaned, and processed into pellets or flakes. They find application in a wide range of industries, including plastic containers, packaging, and consumer goods.

The utilization of recycled plastic products offers several advantages. It contributes to the reduction of waste being dumped in landfills. By reusing plastic materials, valuable resources are conserved, and the reliance on the production of new plastic items is diminished. This aligns with global sustainability goals and waste management objectives. In addition, the production of goods from recycled plastic consumes less energy and resources compared to the manufacturing of new plastic. This results in a reduced carbon footprint and helps mitigate the impact of plastic production on climate change. The environmental benefits of using recycled plastic products are driving consumer preferences towards sustainable alternatives.

Furthermore, the increasing demand for recycled plastic products is stimulating innovation and development in the plastic recycling machine market. To meet the evolving needs of the industry, manufacturers are investing in research and development to create more efficient machines. These advanced machines are capable of processing a broader range of plastic materials, including those utilized in the production of recycled plastic products.

Restraint

High Cost of Plastic Recycling Machine

The global market for plastic recycling machines is severely constrained by the high price of these machines. There are a few justifications for why these machines are costly, including the significant expense of unrefined components, the intricacy of the innovation, and the expense of assembling and transportation. There are a number of reasons why plastic recycling machines cost a lot, including:

- High cost of raw materials: The components used to build plastic recycling machines, such as steel and electronics, can be expensive.

- Complexity of the technology: Plastic recycling machines require advanced technology to process and separate different types of plastic, which can be complex and costly to develop and maintain.

- Low economies of scale: The market for plastic recycling machines is relatively small compared to other industrial machinery, which can result in higher costs due to lower economies of scale.

- High manufacturing and shipping costs: The manufacturing and shipping of plastic recycling machines can be expensive due to the specialized nature of the equipment and the need for quality control.

Market Segmentation

Machine Type Analysis:

Based on machine type, the global plastic recycling machine market is segmented into granulators, shredders, pelletizers, mixers, extrusion machines, crushing machines, agglomeration machines, plastic waste washing machines, and drying machines.

In the plastic recycling machine market, the crushing machines segment is expected to expand at the highest compound annual growth rate (CAGR) of 7.74% from 2024 to 2032, with a share of 18.83% in 2023. Crushing machines, also known as pulverizing machines, are essential in the plastic recycling process as they reduce the size of plastic waste before it is transformed into new products. These machines play a crucial role in turning waste plastic into high-quality recycled materials that can be used in various applications.

Crushing machines make plastic recycling more efficient by processing large amounts of plastic waste quickly and effectively, facilitating the production of high-quality recycled materials. Moreover, incorporating crushing machines in plastic recycling offers environmental benefits. By recycling plastic waste, pollution is reduced, natural resources are preserved, and the amount of plastic ending up in landfills and the environment is minimized.

Application Analysis:

Based on machine type, the global plastic recycling machine market is segmented into granulators, shredders, pelletizers, mixers, extrusion machines, crushing machines, agglomeration machines, plastic waste washing machines, and drying machines.

Post-consumer recycling, which involves the collection, sorting, and processing of waste materials that have been used by consumers, is expected to grow at the highest CAGR of 6.64% over the forecast period. The demand for post-consumer recycling is driven by a combination of environmental, regulatory, technological, and economic factors. As consumers, businesses, and governments prioritize sustainability and waste reduction, the demand for plastic recycling machines capable of effectively processing post-consumer plastics is expected to continue increasing. The awareness of the negative environmental impacts of plastic waste has heightened the demand for post-consumer recycling.

Distribution Channel Analysis:

On the basis of distribution channel, the global plastic recycling machine market is segmented into OEMs (Original Equipment Manufacturers) and aftermarket. The OEMs segment contributed the major share of 83.16% to the global market in 2023, with a valuation of US$ 2,591.17 million. This segment is projected to reach US$ 4,282.03 million by 2032.

The increasing awareness among end-users about the advantages of using OEM products is a key factor driving the demand for original equipment manufacturers in the plastic recycling machine market. OEMs offer superior quality, reliability, and after-sales service, making them a preferred choice for end-users. The benefits provided by OEM products are being increasingly recognized, leading to a willingness to pay a premium for OEM items.

The aftermarket segment is expected to grow at the highest CAGR of 7.93% over the forecast period, primarily driven by the need for maintenance, repair, and replacement of parts. Continuous usage of plastic recycling machines can lead to wear and tear, necessitating periodic replacement of parts. Aftermarket companies provide a range of parts and services specifically designed for the maintenance and repair of plastic recycling machines.

To Understand More About this Research: Request A Free Sample

Geographical Analysis:

North America held the largest market share of 29.49% in the global plastic recycling machine market in 2023. Factors such as environmental awareness, informal regulations, consumer demand for eco-friendly products, technological advancements, and increasing investments contribute to the demand for plastic recycling machines in North America. As North American consumers become more aware of the environmental impact of plastic waste, the demand for plastic recycling machines continues to rise, aiming to reduce plastic waste in the region.

However, Asia-Pacific is expected to exhibit the highest CAGR of 7.48% during the forecast period. The region's large and growing population has led to an increase in plastic consumption. Urbanization has also contributed to this trend as more people migrate to cities and consumer packaged goods. Consequently, both the amount of plastic waste generated in the region and the demand for plastic recycling machines have increased. Additionally, governments in the Asia-Pacific region have implemented various initiatives to promote recycling and reduce plastic waste. For example, China has introduced guidelines to encourage material recycling and imposed restrictions on plastic waste imports. These initiatives have further fueled the demand for plastic recycling machine market in the region.

List of Key Companies Profiled:

- Amstar Machinery Co. Ltd.

- Arlington Machinery

- B+B Anlagenbau

- CP Manufacturing

- Doll Plast

- GENIUS MACHINERY

- Hikon India

- ICMA San Giorgio SpA

- KOWIN

- Munchy

- Netplasmak A

- Next Generation Recyclingmaschinen GmbH

- POLYSTAR MACHINERY CO., LTD.

- Precious Plastic

- PRM-Taiwan

- RECYCLEAN

- Sant Engineering Industries

- Vecoplan

- Other Prominent Players

Recent Developments

- March 2022: ICMA SANGIORGIO, a key player in the supply of industrial machinery, assisted SABIOMATERIALS, an emerging Italian company specializing in green chemistry and eco-friendly plastics, by providing a second compounding line for the production of biodegradable polymers. SABIOMATERIALS was already using an ICMA compounding line for small-scale production. To scale up its manufacturing capabilities, the company incorporated an additional extruder, specifically designed to cater to the unique production requirements of its new materials. Developed using SABIOMATERIALS' proprietary technology, these materials aim to fulfill the increasing demand for sustainable plastics. The company is gaining prominence in the growing sector of materials that are not only biodegradable but also renewable and recyclable.

- June 2021: GENIUS MACHINERY, with over four decades of experience, is rising to the occasion to meet the current market demand for washing machines and waste film recycling. The company, known for delivering comprehensive solutions, has cemented its position, particularly in providing recycling solutions for PE, PP, LDPE, and HDPE, which include plastic washing and drying units. The increased consumption of packaging material has led to a spike in household plastic waste, triggering a surge in demand for film recycling and washing lines from plastic recycling companies. GENIUS is not merely providing its clients with recycling machinery, but it is also dedicated to developing solutions to help reduce carbon footprint. These solutions are designed to be less labor-intensive, energy-efficient, and require minimal maintenance.

Segmental Overview

By Machine Type

- Granulators

- Shredders

- Single Shaft

- Double Shaft

- Pelletizers

- Single Screw

- Twin Screw

- Mixer

- Extrusion Machines

- Crushing Machines

- Agglomeration Machine

- Plastic Waste Washing Machine

- Drying Machines

By Application

- Post Industrial Recycling

- PET Improvement

- Post Consumer Recycling

By Distribution Channel

- OEM

- Aftermarket

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- Western Europe

- The UK

- Germany

- France

- Italy

- Spain

- Rest of Western Europe

- Eastern Europe

- Poland

- Russia

- Rest of Eastern Europe

- Western Europe

- Asia-Pacific

- China

- India

- Japan

- Australia & New Zealand

- South Korea

- ASEAN

- Rest of Asia Pacific

- Middle East and Africa

- Saudi Arabia

- South Africa

- UAE

- Rest of MEA

- South America

- Argentina

- Brazil

- Rest of South America

View Full Infographic

REPORT SCOPE

| Report Attribute | Details |

|---|---|

| Market Size Value in 2023 | US$ 3,127.3 Million |

| Expected Revenue in 2032 | US$ 5,342.2 Million |

| Historic Data | 2019-2022 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Unit | Value (USD Mn) |

| CAGR | 6.13% |

| Segments covered | By Machine Type, By Application, By Distribution Channel, By Region |

| Key Companies | Amstar Machinery Co. Ltd., Arlington Machinery, B+B Anlagenbau, CP Manufacturing, Doll Plast, GENIUS MACHINERY, Hikon India, ICMA San Giorgio SpA, KOWIN, Munchy, Netplasmak A, Next Generation Recyclingmaschinen GmbH, POLYSTAR MACHINERY CO., LTD., Precious Plastic, PRM-Taiwan, RECYCLEAN, Sant Engineering Industries, Vecoplan, Other Prominent Players |

| Customization Scope | Get your customized report as per your preference. Ask for customization |

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

| Report ID: AA0523440 | Delivery: 2 to 4 Hours

| Report ID: AA0523440 | Delivery: 2 to 4 Hours

.svg)