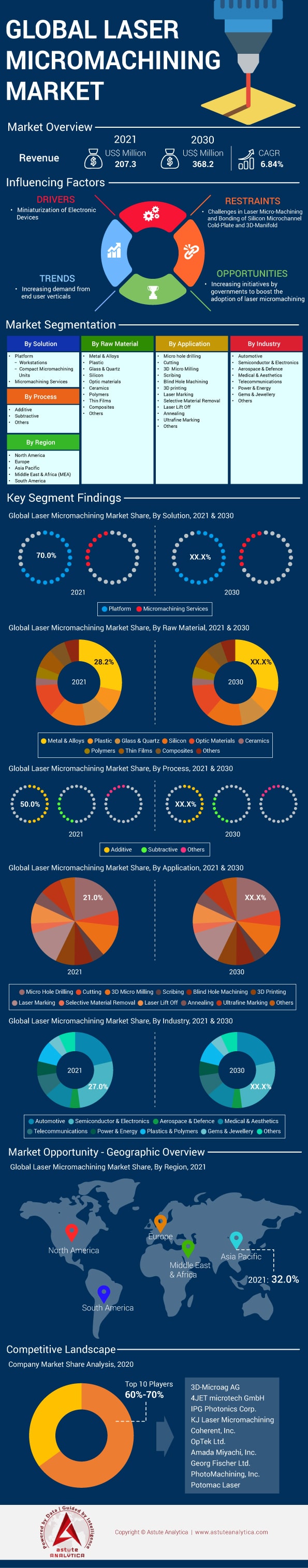

Global Laser Micromachining Market – by Solution (Platform and Micromachining Services); by Raw Material (Metals & Alloys, Plastic, Glass & Quartz Silicon, Optic Materials, Ceramics, Polymers, Thin Films, Composites, and Others); by Process (Additive, Subtractive, and Others); by Application (Micro Hole Drilling, Cutting, 3D Micro Milling, Scribing, Blind hole machining, 3D Printing, Laser Marking, Selective Material Removal, Laser Lift-Off, Annealing, Ultrafine Marking, Others); By Industry (Automotive, Semiconductor & Electronics, Aerospace & Defense, Medical & Aesthetics, Telecommunications, Power & Energy, Plastics & Polymers, Gems & Jewelry, and Others)- Opportunity, Competitive Dashboard, Market Share, Forecast to 2030

- Last Updated: Feb-2022 | Format:

![pdf]()

![powerpoint]()

![excel]() | Report ID: AA0222133 | Delivery: 2 to 4 Hours

| Report ID: AA0222133 | Delivery: 2 to 4 Hours

Laser micromachining is the main tool with which it is possible to obtain microfabrication pushed up beyond the threshold of a single micrometer (one-millionth of a meter). The basic principle for reaching these levels of precision in processing is to use the energy of the radiation almost entirely to chemically interact with the material (tear-off electronic bonds), avoiding heating with thermal side effects.

The increasing trend towards technological miniaturization of mechanical, optical, and electronic devices will drive the global laser micromachining market for future development. Smaller, lighter, and thinner is the product development paradigm of the twenty-first century.

The global laser micromachining market is valued at US$ 207.3 Mn in 2021 and is expected to grow at an annual growth rate of 6.84% over the forecast period of 2022 to 2030. The market is anticipated to record a revenue of US$ 368.2 Mn by 2030.

The report of the global laser micromachining market provides a detailed study of the market including pestle analysis, market share, company profiling, market growth opportunity factor, and the restraints to give an in-depth analysis of the market. The report is divided into 11 parts, totaling 178 pages, 47 extensive tables, and 64 figures.

Report Scope

The global laser micromachining market provides a comprehensive analysis. The increasing urge for the miniaturization of electronic devices supports the market growth. With the advancement in microelectronics and electronics, miniaturization is solving technology challenges across the market, from new frontiers that are enabled by lighter electronics payloads. The report tracks the global region to give an overall study of the market, regions tracked in the report include North America, Europe, Asia Pacific, Middle East & Africa, and South America. North America accounted to have the highest market share of 27.9%, as government funding for the development of micromachining systems, such as that granted by the National Science Foundation (NSF) in the United States. For instance, the US National Science Foundation (NSF) awarded Omax Corporation a Small Business Innovation Research (SBIR) grant in July 2017 for the development of a micromachining abrasive waterjet the MicroMAX JetMachining center capable of positioning precision of fewer than 15 microns.

Furthermore, countries such as China, Japan, and India are coming up with new and advanced technologies, Asia Pacific region is expected to grow at a faster growth rate of 7.45%. Machine learning and Internet of Things (IoT) technologies have led to the introduction of new features, such as an app that broadcasts the status of a system to operators/supervisors on their smartphones or PCs. This has had a favorable impact on market growth. These features allow managers to make proactive decisions and increase the unit's efficiency.

The report also includes the analysis on the following segments – By Solution, by Raw Material, by Process, by Application, and by Industry. Semiconductor and electronics hold the highest share in industry segments in 2020 and 2021, as Silicon has a long history in electronics, optoelectronics, and microelectromechanical systems (MEMS). Despite the silicone material's excellent mechanical properties, its brittleness makes machining difficult, compromising the surface integrity of machined parts. This necessitates additional research in this area to improve the material removal rate and surface integrity. In terms of surface integrity and energy consumption, ultrashort-pulsed laser machining techniques have opened new possibilities for the efficient machining of semiconductor materials.

Moreover, the report covers the hindrance of the market such as challenges in laser micro-machining and bonding of silicon microchannel cold-plate and 3D-manifold.

Report Insight

The global laser micromachining market report provides a complete overview of the market including the market’s recent developments, market concentration rate, opportunity analysis, market competition.

Government funding for the development of micromachining systems, such as that granted by the National Science Foundation (NSF) in the United States and the European Commission (EC), has fueled the significant market growth. In recent years, there has been a surge in the number of consumer-oriented events such as the International Conference on Micromachining. Micromachining is being more widely used in the manufacture of precise instruments, which is propelling market expansion. For example, Mitsubishi Heavy Industries, Ltd. completed the delivery of its ABLASER "laser micromachining equipment to a Japanese precision instrument manufacturer in July 2016.

COVID-19 Impact on Laser Micromachining Market

COVID-19 had a severe impact on the laser micromachining market as their demand plummeted during the pandemic. Additionally, due to the increasing transportation charges and growing prices for raw steel and other raw materials, the prices of laser micromachining have increased.

During the COVID-19 pandemic, manufacturing units and industries across various regions were halted because of lock-down, which further impacted the demand for laser machining. Since the demand decreased drastically, there was a heavy crisis in producing and distributing laser systems globally. Additionally, countries in North America and the Asia Pacific, leading producers faced various challenges due to a significant drop in demand. Further, several plant implementations have gone on hold as there is a severe shortage of raw materials. Moreover, since these systems are used mostly in automotive and manufacturing, among others the manufacturers suffered a heavy loss due to a decrease in production globally

Competitors’ Market in Global Laser Micromachining Market

The global laser micromachining market report provides company profiling of several companies including the company’s business overview, key officials, strategic outlook, product listing, financial details, business segment revenue, and geographical revenue.

The companies included in the report are 3D-Microag AG, 4JET Microtech GmbH, IPG Photonics Corp., KJ Laser Micromachining, OpTek Ltd., Oxford Lasers Ltd, PhotoMachining, Inc., Potomac Laser, Coherent, Inc., Amada Miyachi, Inc., Georg Fischer Ltd.

As per the reported study, the companies provide superb customer satisfaction even for the most complex projects. Companies provide their customers with high-quality, reliable, and user-friendly standard systems for all applications in laser micromachining, also provide branch-specific solutions. Their products help increase production efficiency, optimize processes, and lower costs in various areas of technology.

Segmentation Overview

By Solution

- Platform

- Micromachining Services

By Raw Material

- Metals & Alloys

- Plastic

- Glass & Quartz Silicon

- Optic Materials

- Ceramics

- Polymers

- Thin Films

- Composites

- Others

By Process

- Additive

- Subtractive

- Others

By Application

- Micro Hole Drilling

- Cutting

- 3D Micro Milling

- Scribing

- Blind hole machining

- 3D Printing

- Laser Marking

- Selective Material Removal

- Laser Lift-Off

- Annealing

- Ultrafine Marking

- Others

By Industry

- Automotive

- Semiconductor & Electronics

- Aerospace & Defense

- Medical & Aesthetics

- Telecommunications

- Power & Energy

- Plastics & Polymers

- Gems & Jewelry

- Others

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- The UK

- Germany

- France

- Italy

- Spain

- Poland

- Russia

- Asia Pacific

- China

- Taiwan

- India

- Japan

- Australia & New Zealand

- ASEAN

- Rest of Asia Pacific

- Middle East & Africa (MEA)

- UAE

- Saudi Arabia

- South Africa

- Rest of MEA

- South America

- Brazil

- Argentina

- Rest of South America

View Full Infographic

REPORT SCOPE

| Report Attribute | Details |

|---|---|

| Market Size Value in 2021 | US$ 207.3 Mn |

| Expected Revenue in 2030 | US$ 368.2 Mn |

| Historic Data | 2017-2020 |

| Base Year | 2021 |

| Forecast Period | 2022-2030 |

| Unit | Value (USD Mn) |

| CAGR | 6.84% |

| Segments covered | By Solution, Raw Material, Process, Application, Industry, and Region |

| Key Companies | 3D-Microag AG, 4JET Microtech GmbH, IPG Photonics Corp., and other prominent players. |

| Customization Scope | Get your customized report as per your preference. Ask for customization |

FREQUENTLY ASKED QUESTIONS

Micromachining is a manufacturing technology that involves the use of mechanical micro tools with geometrically defined cutting edges in the subtractive fabrication of devices or features with at least some of their dimensions in the micrometer range.

Laser micromachining can create extremely small features – generally under 1 mm– with a high degree of repeatability and without causing damage to the surrounding material.

The Global Laser Micromachining Market is estimated to grow at a CAGR of 6.84% during the forecast period 2022-2030.

The growing impetus of the laser micromachining market is attributed to miniaturization of electronics devices.

In industries such as healthcare, smaller medical equipment has resulted in painless diagnoses and procedures. Therefore, the demand for micro and nano-sized surgery equipment is increasing in the medical business.

Factors such as high costs associated with micromachining will pose a big-time challenge to the market growth rate.

The Global Laser Micromachining Market is segmented based on solutions, raw materials, process, application, end user industry, and region.

Rising government funding for the development of micromachining systems is an emerging opportunity for the market expansion.

Platform segment has the highest share in the Global Laser Micromachining Market in 2021.

Metals & alloys are major raw materials used in the laser micromachining industry.

In 2021, automotive industry is the highest end user industry in the Global Laser Micromachining Market

Asia Pacific region dominates the Global Laser Micromachining Market in 2021.

The key players in the Global Laser Micromachining Market are 3D-Microag AG, 4JET microtech GmbH, KJ Laser Micromachining, OpTek Ltd., and Georg Fischer Ltd. among others.

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

| Report ID: AA0222133 | Delivery: 2 to 4 Hours

| Report ID: AA0222133 | Delivery: 2 to 4 Hours

.svg)