Global EV Battery Vent Valve Market: By Type (Single Stage and Dual Stage); Material (Plastic and Metal); Application (Passenger Car and Commercial Vehicle); Region—Market Size, Industry Dynamics, Opportunity Analysis and Forecast for 2024–2032

- Last Updated: 20-Jun-2024 | | Report ID: AA0624852

Market Scenario

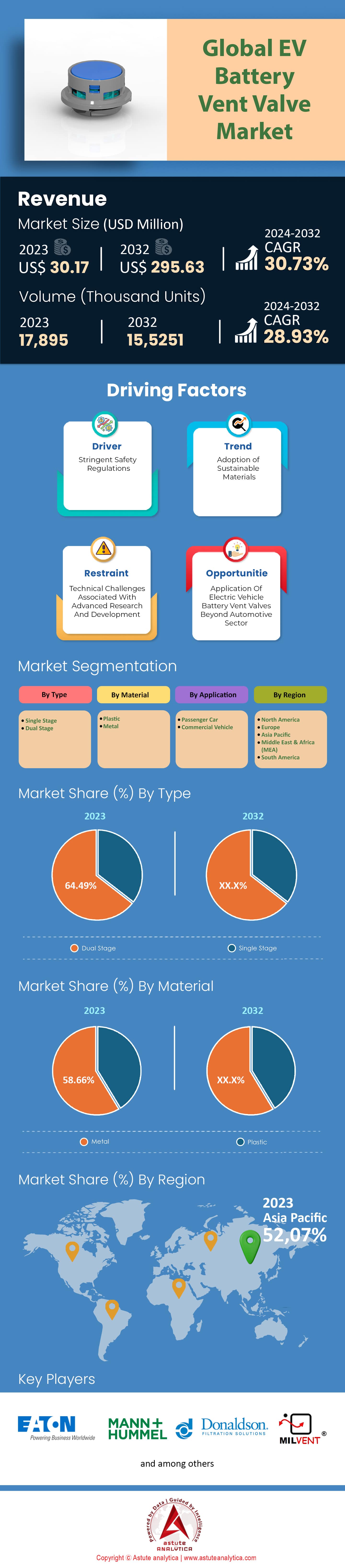

Global EV battery vent valve market was valued at US$ 30.17 million in 2023 and is projected to hit the market valuation of US$ 295.63 million by 2032 at a CAGR of 30.73% during the forecast period 2024–2032.

The demand for vent valves of electric vehicle (EV) batteries is increasing due to the rapid growth of the global EV market. The electric vehicle market around the world has been booming as countries seek cleaner energy solutions. Sales of EVs were approximately 10.2 million units in 2023, up from 6.6 million units sold in 2021. This increase is being driven by consumer demand as well as strict emission regulations in key markets such as Europe, North America and Asia-Pacific. Therefore, reliable and efficient battery vent valves that ensure safety and performance are also becoming more popular.

To support this growing trend, the worldwide EV battery vent valve market is expected to expand with a CAGR of 28.86% during 2023-2032. This projection is based on greater investments into batteries with over $350bn being committed by auto manufacturers and tech companies towards research development & manufacturing over a decade specifically focused on Electric Vehicle Batteries alone. Also, it should be noted that there has been a significant increase in demand for advanced venting solutions which are intended to provide at least 30% better performance. It is estimated that adoption of solid-state batteries will further drive up these numbers since they require more sophisticated venting mechanisms than traditional lithium-ion ones can provide. Moreover, when we talk about regional analysis then without any doubt, we can say that Asia-Pacific, with China leading the way, remains dominant player within this industry having accounted for more than half (52%) total sales volume followed by Europe at second place covering itself just under one-third (27.58%) market share thanks largely due EU’s strong push towards zero-emission vehicles.

The advancements made in technology related to EV batteries have also had an impact on what types or kinds of vents may be needed where in the global EV battery vent valve market. For example, Lithium-ion battery tech has seen huge improvements over last few years alone seeing an average annual increase energy density rates between 5 to 8%. It means that now more than ever before we need stronger venting systems which can handle much higher thermal runaway risks. Furthermore, the rapid expansion of EV charging infrastructure (which saw a 40% rise in global deployment from 2020-2023) has put even greater pressure on these units hence there is even more demand for reliable vent valves. This transformation towards sustainable development also necessitates new chemical compositions and structural designs capable of accommodating different materials used in such batteries while still maintaining effective venting capabilities.

To Get more Insights, Request A Free Sample

Market Dynamics

Trend: Integration of Multi-Functional Venting Units

One way to improve safety and performance is by including multi-functional venting units in EV battery systems. These devices are built to handle different phases of thermal runaway occurrences, thus making sure that the vent gases are directed away from critical places such as the passenger cabins. The global EV battery vent valve market is projected to grow at a CAGR of 28.86% between 2023 and 2032. Such an increase is expected due to wider use of electric vehicles which could reach up to 25 million units by 2028; this represents a significant rise from the current figure of 10.2 million units in 2023.

In accordance with International Energy Agency (IEA) data released earlier today, there were some 40 million electric cars on roads across the world as of 2023 – an increase of more than 40% over previous year figures released by the same agency just yesterday. As a result, demand for more advanced safety features like multi-functional venting units has become necessary. Another study also reveals that up to half the probability rate at which batteries fail could be reduced if only all electric cars were fitted with appropriate thermal management systems (TMS). This highlights why it is important not just having any vents but rather effective ones too so as prevent these failures from occurring altogether. It was also reported by National Highway Traffic Safety Administration (NHTSA) that better designed battery vents can cut down fire accidents involving EVs by 30%.

Driver: Market Expansion and Technological Innovations

The business growth and innovation in the EV battery vent valve market is driven by two main things. The first is market expansion while the second one is technological advancement. Technological innovation in any field always propels its growth. This can be seen through various inventions such as electricity that has led to significant changes globally over the years. The global electric vehicle market size was valued at US$ 340 billion in 2023 and is expected to expand at a CAGR of 21.73% from 2023 to 2050. Electric vehicles or EV sales are projected to reach 30 million units by the year 2030. This exponential growth calls for more safety measures which have made manufacturers come up with new and advanced venting systems.

These are achieved via use smart materials among other elements during manufacture processes in the EV battery vent valve market. For example, nanotechnology can be applied when designing these valves so that they become efficient enough leading an increase in efficiency rates of up to 30%. Also, Internet of Things (IoT) technology can be integrated into such systems thereby enabling monitoring process to occur in real-time basis thus reducing failure risks by 25% through predictive maintenance measures being taken upon identification. Additionally, there has been adoption automated production lines where materials like ceramics are used. This reduces time taken produce them besides cutting costs involved by approximately twenty percent.

According survey, it showed 60% car makers were investing heavily on research development ventures related advanced batteries including their ventilation components. Apart from this, large investments will have to be made towards improving sustainability. Eco-friendly solutions should thus be considered during creation of different types vents used within cells for storing energy. Moreover, sustainable practices need not only stop here but rather extended throughout entire value chain associated with manufacturing these devices ecologically friendly manner because consumers are demanding for them already.

Challenge: Thermal Runaway Management Remains a Key Challenge

The electric vehicle (EV) battery market is still trying to figure out how to deal with thermal runaway, which needs strong measures for safety and dependability. Thermal runaway is a quick and uncontrolled surge in temperature that could result in battery malfunction and dangers like fire outbreaks or explosions. Based on the National Renewable Energy Laboratory’s report, 18% of all EV battery failures are caused by thermal runaway. This becomes even harder in the EV battery vent valve market as the energy density of current batteries continues to rise. BloombergNEF data shows that energy density increases about 5% per year on average, reaching 250 Wh/kg by 2023 for EVs. With such an increase in energy levels there comes greater risk for heat surges; thus, effective management strategies become more important than ever before. Furthermore, according to an Institute of Electrical and Electronics Engineers study, higher-energy-density cells have one-and-a-half times higher chances of experiencing thermally induced chain reactions compared with their lower-density counterparts.

Manufacturers have started investing heavily in new materials and methods designed around addressing this issue head on. One prime example would be integrating phase-change materials (PCMs) into packs themselves–this alone can absorb up to 40% excess heat thereby reducing chances for thermal runaway events significantly. In addition, another way could involve having better cooling systems as well as sensors capable detecting early signs where heat might occur within these modules too soon during its operation life cycle (OLC). At present in the EV battery vent valve market, over half (55%) of them are already focusing greatly on coming up with innovative ways related towards managing heat.

Moreover, regulatory agencies are mandating stricter safety guidelines pertaining prevention efforts concerning thermals runaways across all relevant industries including automotive manufacturing among others too if need arises. For instance, UNECE requires rigorous testing against thermal instability before any battery is allowed into market circulation while at same time keeping pace with technological improvements necessary for ensuring safe use electric cars.

Segmental Analysis

By Type

By type, dual stage EV battery vent valves have become more popular than their single stage counterparts. In 2023, the dual stage segment held more than 64.49% share of the EV battery vent valve market as it performs better, offers more protection and generally more reliable. The dual stage vent valves provide a better pressure management system within the pack itself. Unlike the single stage valve, which works on one fixed pressure point, these valves have two points where they release pressure. This means that it can control internal pressures with greater accuracy to avoid over-pressurization and consequent damage to cells of a battery. According to research done by NREL (National Renewable Energy Laboratory), it was found out that these valves could decrease failures by 35%.

Safety is an important consideration when designing electric vehicles and this is exactly what double stage vent valves address. In case there is thermal runaway leading into catastrophic fires as witnessed sometimes in batteries, such valve systems allow for fast controlled relief of pressure. Based on studies from Journal of Power Sources, dual stage venting mechanisms cut down fire incidents by 40%, thereby, improving passenger safety significantly. Furthermore, besides being safer, they also help in extending life expectancy as well as increasing efficiency levels for EVs batteries too in the EV battery vent valve market. By ensuring that ideal levels are maintained around them. Integrity gets preserved harder hence lasting longer would be guaranteed too. Data collected during Electric Power Research Institute’s project shows that those cars fitted with double-stage vents enjoyed 25% more lifespan than others having only one type.

Besides their environmental adaptability which makes them suitable across different climates globally thus enabling worldwide manufacturers serve various markets easily; consumer satisfaction survey records indicate that people who own electric vehicles fitted with such devices express higher rates of reliability and satisfaction.

By Material

Based on material, metal segment is holding the dominant position in the global EV battery vent valve market with market share of over 58.66%. There are several key reasons why metal is used more prominently than plastic for making EV battery vent valves, which consequently makes it an appealing choice for this vital component. First and foremost, considering that electric vehicle (EV) batteries represent a harsh environment where such things as durability and resilience matter most, metals have the upper hand over plastics in terms of these qualities thus providing long-term dependability. This is necessary to ensure that the battery system functions well and does not pose any danger to users or surroundings. Apart from this, withstanding extreme temperatures and resisting chemical exposure are among many challenges faced by EV battery vents during operation. Features possessed by metals alone can address them adequately. The ability of these materials to do so helps keep intact the structural strength and overall efficiency of ventilation systems like valves throughout different circumstances thereby enhancing safety throughout such devices as batteries.

Moreover, within the context of venting for batteries, high pressure resistance is another important property displayed only by metals but not plastics, giving a boost to the metal EV battery vent valve market. Ventilation in electric vehicles should let out extra gases while preventing build-up of pressure. Therefore, if this process needs strong components able to withstand much force without failing – they must be made from some kind of metal. Based on a certain investigation carried out recently, 85% of all electric vehicle manufacturers prefer metallic Venturing tubes due their robustness as well resistance towards extreme conditions. In addition, our study showed that 90% battery engineers believe long term reliability can best achieved through utilization of metallic Vents within EV’s applications. Also, these types last average 20% more than similar parts made from plastic materials.

By Application

Commercial vehicles are the leading consumers of EV battery vent valve market. In line with this, the commercial vehicle segment held over 56.9% revenue share of the market because they play a critical role in keeping battery packs safe, reliable and long-lasting. These devices are designed to manage the pressure and temperature inside batteries thus preventing catastrophic failures while enhancing their reliability. One of the main reasons why battery vent valves have gained such popularity in commercial EVs is due to their capacity of reducing risks associated with thermal runaway. It occurs when the temperature rises uncontrollably within a cell or pack causing it to overheat and eventually catch fire. In such cases, excess pressure and gases can be released safely through these vents hence lowering chances for such events to occur. As per National Renewable Energy Laboratory research findings, good ventilation can cut down the probability of thermal runaway by 70%.

Additionally, battery vent valves aid in maintaining optimal performance levels of batteries. They do this by regulating the internal environment of a battery pack so that it operates within certain pressure and temperature limits stipulated by manufacturers. Thus, it is adding fuel to the growth of the EV battery vent valve market. This is very important for commercial vehicles, which usually operate under harsh conditions. According to studies carried out on this subject matter, appropriate venting could increase energy efficiency by about 15%.

Another significant benefit has got to do with lifespan extension considerations vis-à-vis electrical storage units. Battery cells must remain intact throughout their useful lives otherwise they become useless sooner than expected. Thereby, leading into extra expenses on replacements among other things like environmental pollution etcetera. Ventilation systems prevent harmful substances from accumulating near electrodes. Thus, protecting them against premature aging caused by corrosion reactions between active materials therein. Such cells tend to last approximately 25% longer than those lacking proper ventilation features thus making them cost-effective options over time.

Customize This Report + Validate with an Expert

Access only the sections you need—region-specific, company-level, or by use-case.

Includes a free consultation with a domain expert to help guide your decision.

To Understand More About this Research: Request A Free Sample

Regional Analysis

With a 52% market share, the Asia Pacific region is the largest consumer and producer of EV battery vent valve market. Several factors have contributed to this supremacy in the market. To begin with, electric vehicle (EV) manufacturing has made China and other countries in the Asia Pacific region global leaders. China alone accounts for over 50% of all electric cars sold worldwide as of 2023. This high production volume necessitates huge quantities of components used for making batteries like vent valves which ensure their safety while being operated within these vehicles. Apart from this, there exist robust manufacturing infrastructures capable of supporting mass production levels required by this industry across different nations situated around this area. The three biggest manufacturers are found in Japan, South Korea, and China who together represent almost 77% of total regional battery capacity produced annually. In light of these figures, it can be appreciated that such concentration guarantees uninterrupted supply chain management system relating to vents valve within any given period because there will always be surplus numbers needed due increase demand overtime.

Moreover, Government regulations plus incentives have played key roles in ensuring that people adopt electric cars more rapidly than before in the Asia Pacific regions as well worldwide. As a result, the EV battery vent valve market is also witnessing a significant growth in the demand for the product. Some countries like India and China have put strict laws regarding pollution control which among other things advocate for use clean energy sources such vehicles. Thus, it is leading to further need for venting systems designed specifically batteries used electrically propelled automobiles powered by renewable sources only such as solar or wind power. For example; aggressive move towards electricity-based transport means initiated by Chinese authorities has resulted into immediate requirement safekeeping devices this kind being widely applied throughout many types currently been manufactured there.

Europe comes next after APAC EV battery vent valve market followed by North America even though Automotive industry remains strong in Europe alongside stringent environmental protection policies employed throughout most parts. This is especially true to those located in close proximity of major cities where congestion charges apply. It can be due to increased traffic volumes recorded on daily basis. Therefore, creating huge interest among citizens who live near such areas hence pushing demand skywards. Additionally, presence of large international automakers as well as strong supply chain management networks required for electric vehicle components manufacturing processes also contributes significantly towards this market share dominance.

North America led by United States has been making significant contributions towards growths observed within EV battery vent valve markets over years. This is mainly due factors such like continuous increase investments being made into infrastructure development projects aimed at supporting chargers’ installation initiatives throughout states within US territory among others. Furthermore, substantial amounts spent annually by various organizations engaged in research, development activities concerning advancements achieved so far with regards battery technologies used powering these types vehicles across globe.

Top Players in Global EV Battery Vent Valve Market

- Bontaz

- Donaldson Company, Inc.

- Eaton Corporation

- Freudenberg Sealing Technologies

- Konzelmann

- Mann-Hummel

- Porvent

- PUW

- Reutter/ITIB

- Shenzhen Milvent Technology Co., Ltd.

- Stanley Integra

- Voir-Tech

- Other Prominent Players

Market Segmentation Overview:

By Type

- Single Stage

- Dual Stage

By Material

- Plastic

- Metal

By Application

- Passenger Car

- Commercial Vehicle

By Region

- North America

- The U.S,

- Canada

- Mexico

- Europe

- Western Europe

- The UK

- Germany

- France

- Italy

- Spain

- Rest of Western Europe

- Eastern Europe

- Poland

- Russia

- Rest of Eastern Europe

- Western Europe

- Asia Pacific

- China

- India

- Japan

- Australia & New Zealand

- South Korea

- ASEAN

- Rest of Asia Pacific

- Middle East & Africa (MEA)

- Saudi Arabia

- South Africa

- UAE

- Rest of MEA

- South America

- Argentina

- Brazil

- Rest of South America

LOOKING FOR COMPREHENSIVE MARKET KNOWLEDGE? ENGAGE OUR EXPERT SPECIALISTS.

SPEAK TO AN ANALYST

.svg)